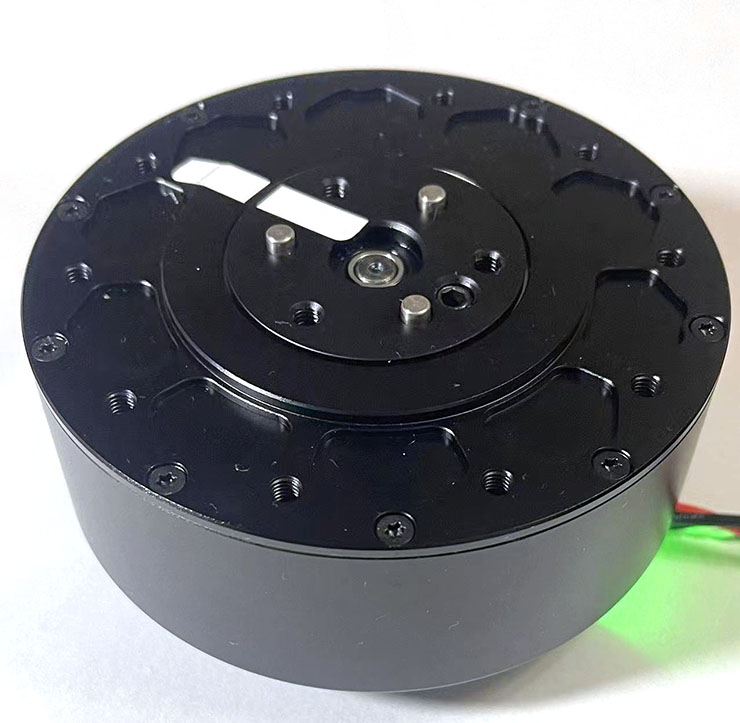

MG8008-9 Duo V3 2 encoders Robot dog motor with gear box & CAN driver 18 bit on motor 14 bit on gearbox Stator 8008 KV42

Availability: 49994

Ex Tax: $296.20

8 or more $287.90

Add to Compare

25380087 MG8008-9 1:9 Duo V3 2 encoders Robot dog Motor with Gear box & CAN Driver, Stator 8008 KV42

Specifications:

| Motor | MG Series Motors | |||||||||||||

| Part No. | 4005 -10 | 4010 -10 | 4010 -36 | 5010 -10 |

6010-6 |

6012 -8 |

6012 -36 | 8008 -9 | 8010 -6 | 8010 -36 | 8016 -6 | 10015 -10 | ||

| Turns | 25 | 14 | 14 | 13 | 20 | 20 | 20 | 17 | 17 | 13 | 13 | 11 | ||

| Nominal voltage | V | 24 | 24 | 24 | 24 | 48 | 48 | 48 | 48 | 48 | 48 | 48 | 48 | |

| Nominal current | A | 1.6 | 3.5 | 3.5 | 4.4 | 3.8 | 3.8 | 3.8 | 4.9 | 4.9 | 6.9 | 6.5 | 8 | |

| Nominal power | 38.4 | 84 | 84 | 106 | 182.4 | 182.4 | 182.4 | 240 | 240 | 330 | 330 | 385 | ||

| Nominal torque | N.M | 1 | 2.5 | 9 | 4 | 5 | 5 | 15 | 10 | 9 | 35 | 13 | 30 | |

| Nominal Speed | rpm | 253 | 260 | 72 | 235 | 285 | 285 | 62 | 178 | 155 | 68 | 155 | 150 | |

| Max Speed | rpm | 316 | 320 | 90 | 320 | 350 | 350 | 78 | 220 | 225 | 80 | 225 | 190 | |

| Stall torque | N.M | 2.5 | 4.5 | 18 | 7 | 11.5 | 11.5 | 33 | 20 | 21 | 45 | 35 | 50 | |

| Stall current | A | 4 | 6.97 | 6.97 | 6.7 | 8 | 8 | 8 | 10 | 7 | 9 | 12.5 | 13 | |

| Resistance | Ω | 1.4 | 0.6 | 0.6 | 0.47 | 0.98 | 0.98 | 0.98 | 0.74 | 0.94 | 0.27 | 0.55 | 0.38 | |

| Wire connect | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | ||

| Phase to phase inductance | mH | 0.5 | 0.28 | 0.28 | 0.26 | 0.55 | 0.55 | 0.55 | 0.59 | 0.73 | 0.23 | 0.54 | 0.45 | |

| Speed constant | rpm/v | 105 | 108 | 3 | 98 | 58 | 58 | 58 | 42 | 32 | 51 | 30 | 28 | |

| Torque constant | N.M/A | 0.06 | 0.07 | 2.58 | 0.1 | 1.32 | 1.32 |

3.94 |

2.07 | 3.00 | 5.07 | 3.30 | 3.85 | |

| Radial load | N | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 | 1200 | 2000 | |

| Axial load | N | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 500 | |

| Rotor inertia | gc㎡ | 140 | 202 | 850 | 850 | 850 | 1550 | 805 | 2670 | 3400 | 5675 | |||

| Number of poles | pairs | 13 | 13 | 13 | 14 | 14 | 14 | 14 | 20 | 20 | 20 | 20 | 21 | |

| Motor weight | g | 154 | 250 | 350 | 420 | 480 | 480 | 570 | 630 | 860 | 710 | 1190 | ||

| Working temperature | C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | |

| Max demagnetize temperature | C | 120C | 120C | 120C | 120C | 120C | 120C | 120C | 120C | 120C | 120C | 120C | 120C | |

| Gear | Gear ratio | 10:1 | 10:1 | 36:1 | 10:1 | 6:1 | 8:1 | 36:1 | 9:1 | 6:1 | 36:1 | 6:1 | 10:1 | |

| Backlash | 10 | 8 | 6 | 8 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | ||

| Driver | Driver No. | DG40 | DG40 | DG40 | DG40 | DRC15 | DRC15 | DRC15 | DRC20 | DRC20 | DRC20 | DRC20 | DRC20 | |

| Input voltage | V | 7.4-32 | 7.4-32 | 7.4-32 | 7.4-32 | 12-48 | 12-48 | 12-48 | 12-48 | 12-50 | 12-50 | 12-50 | 12-50 | |

| Nominal Current | A | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 15 | 15 | 15 | 15 | 15 | |

| Burst Current | A | 15 | 15 | 15 | 15 | 20 | 20 | 20 | 30 | 30 | 30 | 30 | 30 | |

| Nominal power | W | 120 | 120 | 120 | 120 | 300 | 300 | 300 | 700 | 700 | 700 | 700 | 700 | |

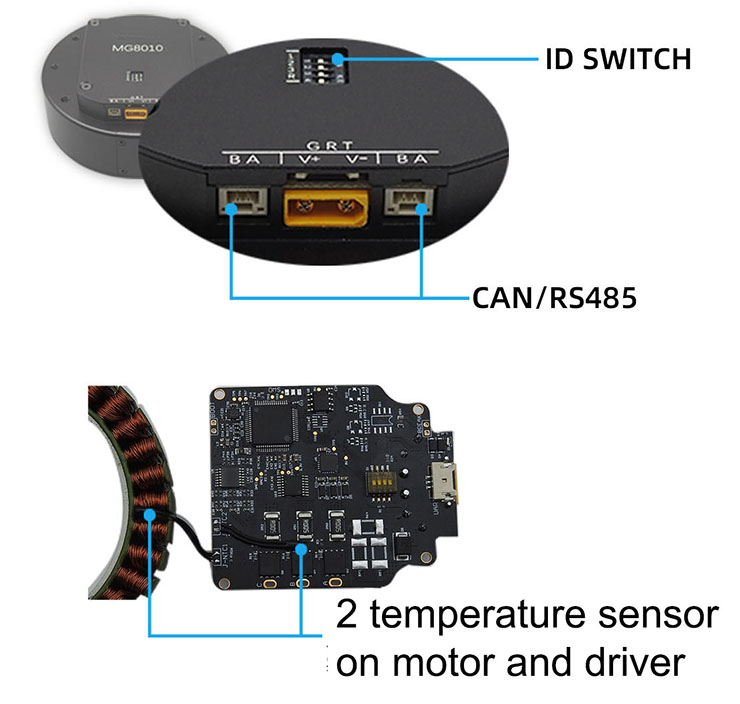

| Communication | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | CAN/ RS485 | ||

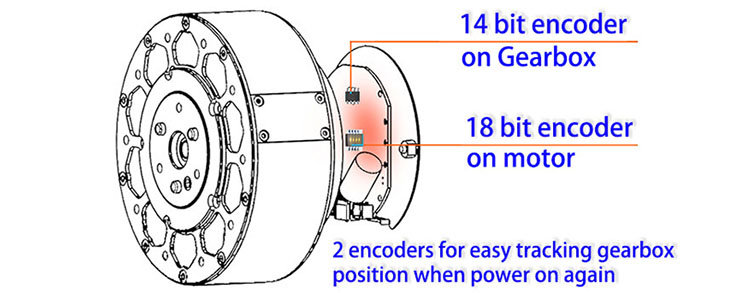

| Encoder | 14-bit | 18-bit | 18-bit | 18-bit | 16-bit | 16-bit | 16-bit | 18-bit | 18-bit | 18-bit | 18-bit | 18-bit | ||

| 2 Encoders | No | OPT | OPT | OPT | OPT | OPT | No | OPT | No | No | OPT | OPT | ||

| Baut rate | 1M | 1M | 1M | 1M | 1M | 1M | 1M | 1M | 1M | 1M | 1M | 1M | ||

| Communication frequency | 2K | 2K | 2K | 2K | 2K | 2K | 2K | 2K | 2K | 2K | 2K | 2K | ||

| Control frequency | ||||||||||||||

| Torque loop | kHz | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 32 | 32 | 32 | 32 | 24 | |

| Speed loop | kHz | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| Position loop | kHz | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Control mode | ||||||||||||||

| Torque loop | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| Speed loop | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| Position loop | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| S-Curve | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| ID Switch | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| Connector | ZH | ZH | ZH | ZH | XT30 | XT30 | XT30 | XT30 | XT30 | XT30 | XT30 | XT30 | ||

| Temperature sensor | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

You are welcome to customize the motor, such as: color, reduction ratio, installation hole position, and other specifications!

Two Encoder Benifits

|

|

|

|

The first encoder remembers the motor rotor zero postion. The second encoder remembers the gear box output shaft zero position. |

3. Send command 3E A6 01 08 ED 00 00 71 02 A0 8C 00 00 9F in Hex to make the motor return to 267 degree position. |

6. Send command 3E A6 01 08 ED 00 00 00 00 A0 8C 00 00 2C in Hex to make the motor return to Zero position. |

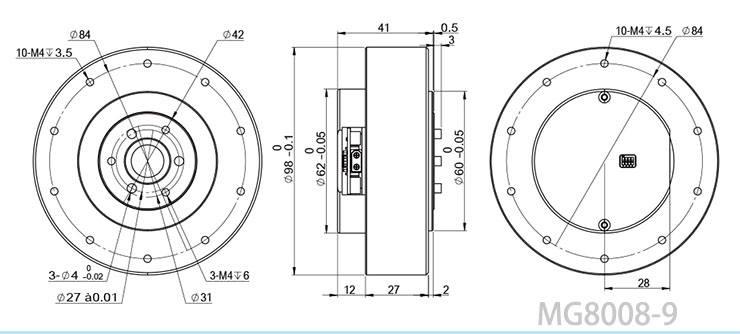

Drawing:

Related product list for easy finding the suitable one:

| MIT open source software | Commercial software | ||||||||||

| MIT60 | MIT80 | MIT80 Pro | MG6010 | MG6012 Duo | MG8010 | MG8016 | MG8016 Duo | MG10015 | |||

| Motor | Power supply | V | 24 | 24 / 48 | 48 | 48 | 48 | 48 | 48 | 48 | 48 |

| Current | A | 7.4 | 7 | 6.5 | 3.8 | 3.8 | 4.9 | 6.5 | 6.5 | 8 | |

| Torque | N.M | 3 | 9 | 13 | 5 | 5 | 9 | 13 | 13 | 30 | |

| Torque const. | N.M/A | 1.3 | 2.4 | 3.1 | 1.32 | 1.32 | 3.00 | 3.30 | 3.30 | 3.85 | |

| Rated speed | rpm | 300 | 160 | 300 | 285 | 285 | 165 | 155 | 155 | 150 | |

| Max speed | rpm | 400 | 245 | 380 | 350 | 350 | 250 | 225 | 225 | 190 | |

| Speed const. | rpm/v | 140 | 100 | 100 | 58 | 62 | 32 | 30 | 30 | 28 | |

| Resistance | Ω | 0.26 | 0.17 | 0.161 | 0.98 | 0.98 | 0.94 | 0.55 | 0.55 | 0.38 | |

| Inductance | mH | 0.112 | 0.057 | 0.073 | 0.55 | 0.55 | 0.73 | 0.54 | 0.54 | 0.45 | |

| Poles | 14 | 21 | 21 | 14 | 14 | 20 | 20 | 20 | 21 | ||

| Motor power | W | 210 | 200 | 480 | 182.4 | 182.4 | 240 | 330 | 330 | 385 | |

| Size | mm | 76x63.5 | 96x39.5 | 96x41.7 | 79x44.7 | 80x44.5 | 98x43 | 99x49.5 | 99x49.5 | 120x50.2 | |

| Max motor temperature | C | 85C | 85C | 85C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | -20 - 80C | |

| Gearbox | Gear rate | 6:1 | 6:1 | 6:1 | 8:1 | 8:1 | 6:1 | 6:1 | 6:1 | 7:1 | |

| Stall torque | N.M | 9 | 15 | 35 | 11.5 | 11.5 | 21 | 35 | 35 | 50 | |

| Driver | Encoder | 12bit | MA702 15bit | 12bit | 16-bit | 16-bit | 16-bit | 16-bit | 18-bit | 18-bit | |

| Encoders | pcs | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 2 | 1 | |

| Position control mode | kHz | 2 | 2 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Protection | stall warning | Over current/over heat | |||||||||

| Communication | SmartCAN 1MHz | CAN Bus/RS485 | |||||||||

| Firmware | MIT open source software | Commercial software/ Torque loop/Position loop/Speed loop | |||||||||

| Assembly | Ambient temperature | C | 0-40C | 0-40C | 0-40C | -20-40C | -20-40C | -20-40C | -20-40C | -20-40C | -20-40C |

| Weight | g | 315g | 600g | 714g | 480 | 480 | 630 | 710 | 710 | 1190 |

|

Applications:

Open CAN Protocol

1. CAN bus parameters and single motor command send and receive message format

Bus interface: CAN

Baud rate: 1Mbps

The format of message used to send commands and motor replies to a single motor is as follows:

ID: 0x140 + ID(1~32)

Frame format: DATA

Frame type: Standard

DLC: 8 Byte

English

English