GIM4310-36 Robot dog motor with 36:1 gear box Stator 4310 10Nm 110KV with MIT CAN Driver

Ex Tax: $184.80

12 or more $182.80

Add to Compare

2564310362 GIM4310-36 Robot dog motor with 10:1 gear box Stator 4310 10Nm 110KV with MIT CAN Driver

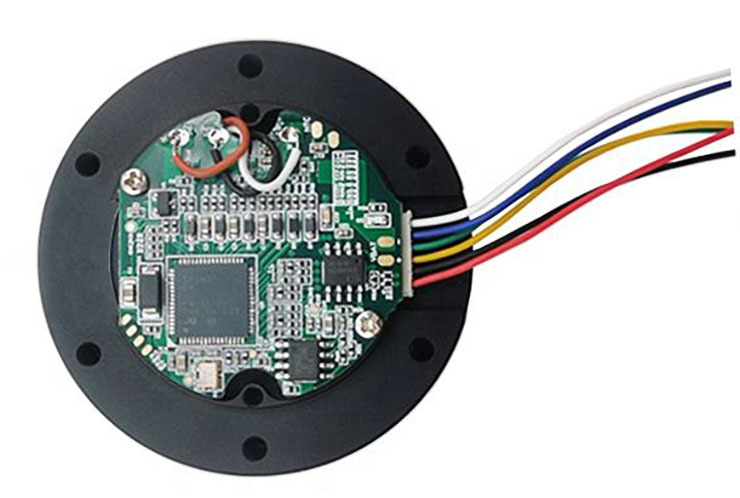

Driver: New driver

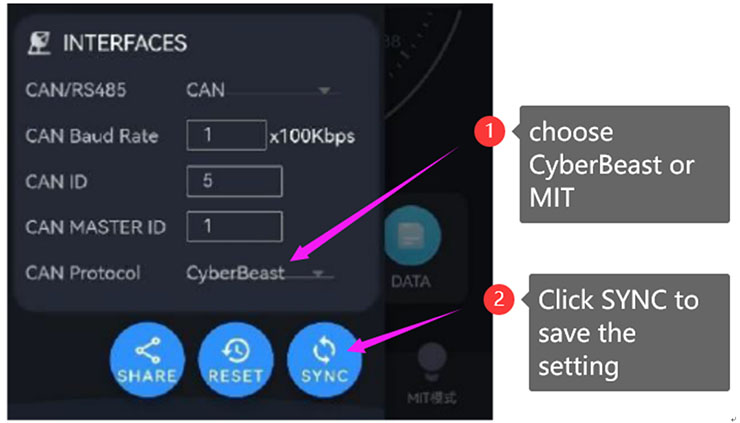

- Supports MIT CAN and CyberBeast CAN protocol. You can choose MIT CAN or Cyberbeast CAN protocol for communication.

- CyberBeast protocol supports CAN or RS485 protocol communications.

- Supports voltage, temperature reading. (0xB4 00 00 00 00 00 00 00 Read the voltage)

- Supports Ia, Ib, Ic,current reading. (0xB4 04 00 00 00 00 00 00 Read the Ia)

- Supports Torque control. (0x93 CC CC 7C 41 B8 0B 00 15.8Nm )

- Supports Speed control. (0x94 00 00 4A 42 B8 0B 00 50.5RPM )

- Supports Positoin control. (0x95 00 10 49 40 B8 0B 00 180degree)

- There are Windows PC App and Android App for mobile phone to set and test the motor. You can use USB to TLL for wire connectoin, or MotorWifi for wireless connection.

Specifications:

| GIM Series Motor with GearBox 35 & 43 | ||||||||||

| GIM | 3505-8 | 3505-9 | 3505-36 | 3510-8 | 3510-64 | 4305-10 | 4310-10 | 4310-36 | 4310-40 | 4315-8 |

| Nominal Voltage V | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Voltage Range V | 12-40 | 12-40 | 12-40 | 12-40 | 12-40 | 12-40 | 12-40 | 12-40 | 12-40 | 12-40 |

| Nominal Current A | 1.4 | 1.6 | 1.7 | 3.3 | 3.41 | 4.0 | 3.5 | 3.0 | 3.7 | 1.86 |

| Max Current A | 2.5 | 4.19 | 4.54 | 28.94 | 25.58 | 13 | 15 | 12 | 17.1 | 19.5 |

| Nominal Torque Nm | 0.43 | 0.71 | 3.12 | 1 | 9 | 0.85 | 3 | 6 | 8.5 | 1.6 |

| Max Torque Nm | 0.85 | 1.95 | 8.01 | 6.28 | 50 | 3 | 5.8 | 18 | 30.59 | 14.25 |

| Torque const. Nm/A | 0.41 | 0.35 | 2.0 | 0.28 | 2.84 | 0.21 | 0.66 | 1.5 | 1.79 | 0.96 |

| Planet Gear box Rate | 8:1 | 9:1 | 36:1 | 8:1 | 64:1 | 10:1 | 10:1 | 36:1 | 40:1 | 8:1 |

| Rated Gear shaft rpm | 234 | 258 | 50 | 534 | 67 | 200 | 100 | 28 | 70 | 350 |

| Max Gear shaft rpm | 306 | 380 | 97 | 588 | 74 | 540 | 300 | 85 | 86 | 405 |

| Speed const. KV | 13 | 15.83 | 4.04 | 24.5 | 3.08 | 15 | 9 | 2.5 | 3.58 | 16.88 |

| Res ohm | 4.03 | 4.47 | 4.47 | 0.52 | 0.52 | 0.64 | 1.05 | 0.97 | 0.27 | 1.5 |

| L mH | 0.43 | 0.45 | 0.45 | 0.29 | 0.29 | 0.17 | 0.34 | 0.33 | 0.8 | 0.43 |

| Poles pairs | 11 | 11 | 11 | 7 | 7 | 14 | 14 | 14 | 14 | 14 |

| Motor power W | 9 | 38 | 41 | 79 | 82 | 20 | 20 | 12 | 89 | 45 |

| Size dia mm | 43 | 45 | 45 | 46 | 46 | 53 | 53 | 55 | 57 | 57 |

| Size L mm | 30 | 36.1 | 44.1 | 51.5 | 77.5 | 26 | 32 | 47 | 56 | 58 |

| Max motor temp. 0C | -20-+80 | -20-+80 | -20-+80 | -20-+80 | -20-+80 | -20-+80 | -20-+80 | -20-+80 | -20-+80 | -20-+80 |

| Gear backlash arcmin | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Encoder bit | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

| Weight g | 97 | 132 | 178 | 259.6 | 507 | 150 | 227 | 310 | 385 | 372 |

| GIM Series Motor with GearBox 60, 81 &100 | |||||||||||||||||||||

| GIM | 6010-6 |

6010-8-Lite |

6010-36 | 8108-6 | 8108-8-Lite | 8108-9 | 8108-36 | 8115-6 | 8115-9 | 8115-36 | 10015-9 | ||||||||||

| Motor | Nominal Voltage V |

24 | 24 | 24 | 24 | 24 | 24 | 48 | 48 | 24 | 48 | 24 | 48 | 48 | 48 | 48 | 48 | 48 | 48 | 24 | 48 |

| Voltage Range V | 12-36 | 24-48 | 24-56 | 24-48 | 36-48 | 10-40 | 24-48 | ||||||||||||||

| Nominal Current A | 24 | 4 | 10.5 | 8 | 4 | 5 | 14.5 | 7 | 5 | 15 | 5 | 16 | 16 | 5 | 9.5 | 5 | 9.5 | 5 | 17.5 | 12 | |

| Max Current A | 40 | 15 | 25 | 20 | 15 | 20 | 45 | 25 | 20 | 45 | 20 | 45 | 45 | 20 | 45 | 20 | 25 | 20 | 35 | 35 | |

| Nominal Torque Nm | 3 | 3 | 5 | 24 | 18 | 6 | 6.5 | 7.5 | 9 | 9 | 36 | 33 | 11 | 9 | 17 | 13 | 45 | 54 | 25 | 28 | |

| Max Torque Nm | 9 | 9 | 11 | 58 | 45 | 15 | 17 | 22 | 22 | 22 | 90 | 93 | 29.5 | 25 | 45 | 35 | 115 | 150 | 60 | 70 | |

| Torque const. Nm/A | 0.1 | 0.07 | 0.47 | 3.05 | 0.07 | 0.09 | 0.45 | 1.0 | 0.09 | 0.6 | 0.09 | 2.05 | 0.7 | 0.28 | 1.55 | 0.28 | 4.8 | .28 | 1.37 | 2.41 | |

| Rated Gear shaft speed rpm | 320 | 300 | 120 | 30 | 50 | 200 | 250 | 110 | 130 | 180 | 35 | 40 | 140 | 180 | 110 | 120 | 15 | 30 | 50 | 45 | |

| Max Gear shaft speed rpm | 670 | 400 | 420 | 69 | 90 | 350 | 650 | 320 | 230 | 400 | 65 | 110 | 330 | 380 | 220 | 250 | 36 | 65 | 155 | 122 | |

| Speed const. KV | 19 | 130 | 12 | 1.9 | 130 | 100 | 14 | 5.7 | 100 | 9.4 | 100 | 2.5 | 7.1 | 50 | 4.8 | 50 | 4.8 | 50 | 4.5 | 2.5 | |

| Res ohm | 0.32 | 0.28 | 0.21 | 0.32 | 0.2 | 0.28 | 0.13 | 0.44 | 0.28 | 0.16 | 0.28 | 0.12 | 0.23 | 0.43 | 0.23 | 0.43 | 0.54 | 0.43 | 0.14 | 0.43 | |

| L mH | 0.2 | 0.2 | 0.12 | 0.23 | 0.19 | 0.17 | 0.06 | 0.04 | 0.17 | 0.05 | 0.17 | 0.05 | 0.09 | 0.27 | 0.26 | 0.27 | 0.26 | 0.27 | 0.09 | 0.27 | |

| Poles pairs | 14 | 14 | 14 | 14 | 14 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | |

| Motor power W | 85 | 90 | 65 | 75 | 90 | 125 | 170 | 80 | 125 | 170 | 125 | 135 | 160 | 160 | 195 | 160 | 85 | 160 | 130 | 130 | |

| Size dia mm | 76 | 76 | 80 | 76 | 76 | 96 | 96 | 92 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 122 | 122 | |

| Size L mm | 35 | 35 | 40 | 56.5 | 56.5 | 41.5 | 41.5 | 55 | 41.5 | 41.5 | 57 | 57 | 48.5 | 48.5 | 48.5 | 48.5 | 64 | 64 | 57.5 | 57.5 | |

| Max motor temp. 0C | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | |

| Gear box |

Type | Planetary | |||||||||||||||||||

| Gear rate | 6:1 | 6:1 | 8:1 | 36:1 | 36:1 | 6:1 | 6:1 | 8:1 | 9:1 | 9:1 | 36:1 | 36:1 | 6:1 | 6:1 | 9:1 | 9:1 | 36:1 | 36:1 | 9:1 | 9:1 | |

| Stall torque Nm | 40 | 15 | 25 | 20 | 15 | 20 | 45 | 25 | 20 | 45 | 20 | 45 | 45 | 20 | 45 | 20 | 25 | 20 | 35 | 35 | |

| Gear backlash arcmin |

15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | |

| Gear material | Steel | ||||||||||||||||||||

| Driver | Encoder | ||||||||||||||||||||

| Position control mode |

2KHZ | ||||||||||||||||||||

| Protection | Stall OTP | ||||||||||||||||||||

| Communication |

UART / CAN |

||||||||||||||||||||

| FW | MIT / ZE / CB | OD ZE |

MIT / ZE / CB | OD ZE |

MIT / ZE / CB | ||||||||||||||||

|

Motor & Gear |

Ambient temp. 0C | 0-40 | |||||||||||||||||||

| Max. Axial load N | 600 | 600 | 600 | 900 | 900 | 800 | 800 | 800 | 800 | 800 | 900 | 900 | 800 | 800 | 800 | 800 | 900 | 900 | 5k | 5k | |

| Max. Radial load N | 800 | 800 | 800 | 1k | 1k | 900 | 900 | 900 | 900 | 900 | 1k | 1k | 900 | 900 | 900 | 900 | 1k | 1k | 5k | 5k | |

| Size dia mm | 76 | 76 | 80 | 76 | 76 | 96 | 96 | 92 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 122 | 122 | |

| Size L mm | 35 | 35 | 40 | 56.5 | 56.5 | 41.5 | 41.5 | 55 | 41.5 | 41.5 | 57 | 57 | 48.5 | 48.5 | 48.5 | 48.5 | 64 | 64 | 57.5 | 57.5 | |

| Weight g | 318 | 318 | 388 | 574 | 574 | 567 | 567 | 396 | 567 | 567 | 760 | 760 | 705 | 705 | 705 | 705 | 960 | 960 | 1372 | 1372 | |

Driver Specifications:

| Item | Data and Specification |

| Rated Voltage | 0-26V, support 6S Lipo battery |

| Rated Current | 3A |

| Max Voltage | 30V |

| Peak Current | 6A |

| Encoder | 14 bit |

| PWM |

Control the motor rotation according to the configuration mode |

| RS485 | Driver parameter adjustment interface, firmware upgrade interface. RS485 baud rate is 19200, 8-bit data, no check, 1stop bit All RS485 commands end with 0x0D 0A (with Enter key value) All data written through the RS485 interface are stored in the chip at once. |

| CAN | Bus control interface, compatible with MIT control protocol |

| ENCODER2 | The second encoder interface is used to set up the absolute position |

MIT CAN control:

CANBUS protocol and commands, these commands are compatible with MIT Cheetah CAN

CAN data frame length 8 byte.

CAN Baudrate: 1Mbps

Default CAN ID: 1 (you can set the motor driver ID by RS485)

1) Control the motor

0xff 0xff 0xff 0xff 0xff 0xff 0xff 0xfc // Start the motor

0xff 0xff 0xff 0xff 0xff 0xff 0xff 0xfd // Stop the motor

2) Set the motor position zero point

0xff 0xff 0xff 0xff 0xff 0xff 0xff 0xfe

3)Switch the motor operation mode

0xff 0xff 0xff 0xff 0xff 0xff 0xff 0xf9 //Switch to torque mode

0xff 0xff 0xff 0xff 0xff 0xff 0xff 0xfA //switch to speed mode

0xff 0xff 0xff 0xff 0xff 0xff 0xff 0xfB //Switches to position mode

4) Running data samples of Continuous data in position mode:

Send 00000001 8 00 00 80 F8 88 86 63 E8

Receive 00000064 6 01 FF FF 80 07 AB

Send 00000001 8 00 00 80 F8 88 86 63 E8

Receive 00000064 6 01 D4 7E 49 67 3C

Send 00000001 8 00 00 80 F8 88 86 63 E8

Receive 00000064 6 01 8F 12 38 77 AC

Send 00000001 8 00 00 80 F8 88 86 63 E8

Receive 00000064 6 01 3E BA 32 67 DA

Send 00000001 8 FF FF 7D 08 88 86 63 E8

Receive 00000064 6 01 00 1F 80 08 23

Send 00000001 8 FF FF 7D 08 88 86 63 E8

Receive 00000064 6 01 17 B5 AC 98 D8

Send 00000001 8 FF FF 7D 08 88 86 63 E8

Receive 00000064 6 01 44 40 C0 C9 38

Send 00000001 8 FF FF 7D 08 88 86 63 E8

Receive 00000064 6 01 7C 2D CB 57 F7

Send 00000001 8 FF FF 7D 08 88 86 63 E8

Receive 00000064 6 01 B8 E6 CF 28 31

Notes:

CAN Send: Identifier: 0x00 Standard Frame Frame Format: DATA DLC: 8 bytes

| DATA[0] | DATA[1] | DATA[2] | DATA[3] | DATA[4] | DATA[5] | DATA[6] | DATA[7] | |||

| Data bit | 7-0 | 7-0 | 7-0 | 7-0 | 7-4 | 3-0 | 7-0 | 7-4 | 3-0 | 7-0 |

| Content | high 8 bits | low 8 bits | high 8 bits | low 4 bits | high 4 bits | low 8 bits | high 8 bits | low 4 bits | high 4 bits | low 4 bits |

| Motor position | Motor speed | KP | KD | torque | ||||||

| Value |

Copyright © 2003-2017 by SMC Powers Ltd. All Rights Reserved. Email: shop@smc-powers.com Skype:smc-power

| |||||||||

English

English